Technology:

Woodgrain series panels usually use 3d digital printing technology, transfer printing technology or embossing technology to achieve a realistic woodgrain effect. Digital printing allows for precise control of colour and texture details; transfer printing transfers the wood grain pattern to the surface of the panel in its entirety; and embossing uses a mould to create a concave-convex wood grain on the surface of the panel.

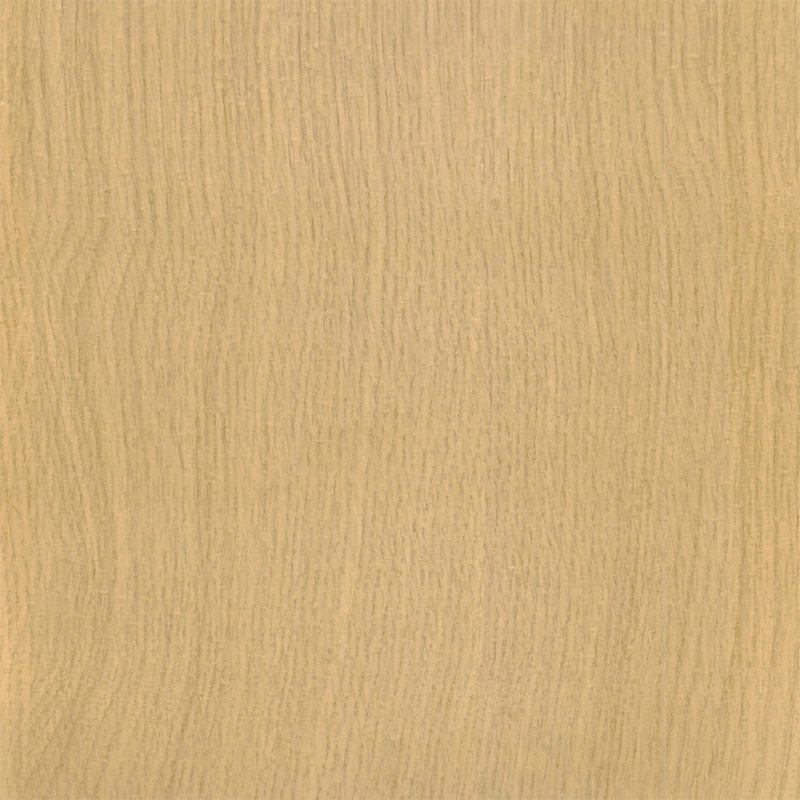

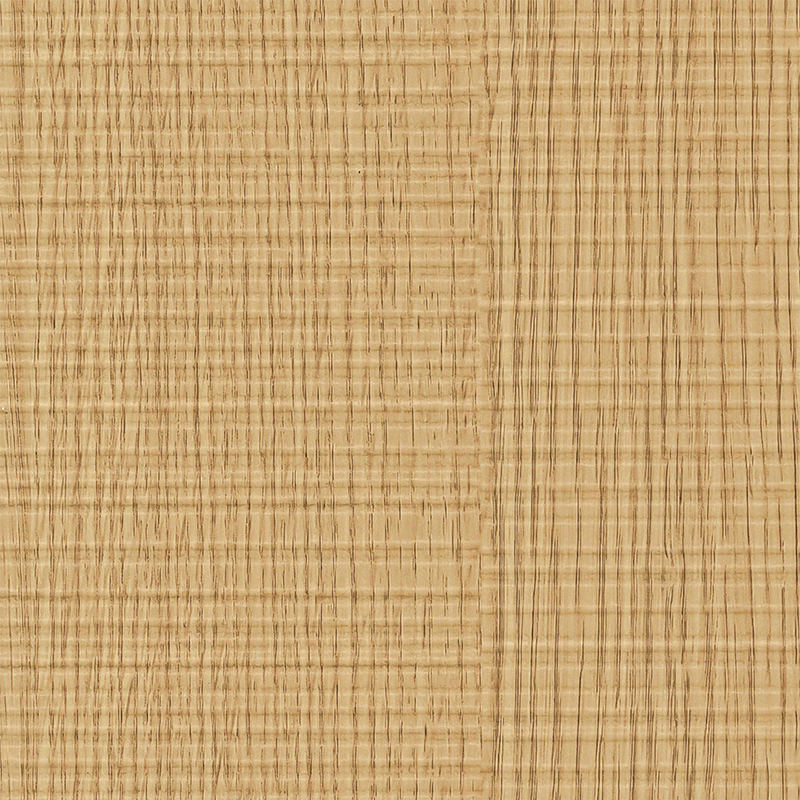

Design Principle:

The design aims to mimic the grain, colour and texture of a variety of natural wood species to satisfy the desire for natural wood aesthetics while providing a more economical, sustainable and stable material choice. Through the study of grain characteristics of different wood species, including annual rings, wood rays, tube holes, etc., accurate reproduction and artistic processing are carried out.

Hot pressing process:

During the hot pressing process, the temperature, pressure and time are strictly controlled according to the material of the panel and the expected performance requirements. The high temperature makes the adhesive in the plate fully cured, and the pressure prompts the layers of material to be closely combined to form a solid plate structure, and at the same time makes the wood grain pattern better integrated into the surface of the plate.

Product structure and raw materials:

The product structure may be a multi-layer structure, including the base layer, core layer and the surface of the wood grain decorative layer. Raw materials are often man-made panels, such as particle board, medium-density fibreboard, or polymer materials, etc., and environmentally friendly adhesives are used.

Characteristics of wood grain texture:

The texture has clear lines, simulating the growth of the wood's annual cycle, the direction of the wood grain and natural imperfections, such as knots, cracks and so on. The colour will also show the natural tone of the wood, ranging from light yellow to dark brown.

Features:

Realistically reproduces the appearance of natural wood, giving a natural, warm feeling; the grain is rich and varied and can mimic a wide range of wood species.

Advantage:

Compared with solid wood, it has a more stable performance and is not easy to deform and crack; relatively low price, cost-effective; sustainable, reducing the dependence on natural wood.

Role (Function):

Mainly used in furniture manufacturing, and interior decoration, such as making cabinets, wardrobes, flooring, wall panels, etc., to create a natural and comfortable atmosphere for the space.

Application (Usage):

Widely used in various areas of home space, such as bedrooms, living rooms, kitchens, etc.; also commonly used in commercial places, such as offices, restaurants, shopping malls, etc. decoration.

中文简体

中文简体