YAKCO New Materials (Jiangsu) Co., Ltd. was established in 2007.It is a professional China Frosted 3D Melamine Board Manufacturers and Frosted 3D Melamine Board Factory.The company covers an area of 50 acres and has a modern standard factory building of over 30000 square meters. For over a decade, we have been deeply researching the construction characteristics of home and commercial spaces, committed to the research and production of high-end decorative panels and wall panels.

——To align with the design quality of international top brands and create its exclusive advantages in the production cycle, YAKCO added a fully automatic (paint-free board surface treatment) short cycle fast press with a value of about 15 million yuan in 2018, focusing on deep pressing and multi-width, to bring the product surface treatment process in line with international top brands.

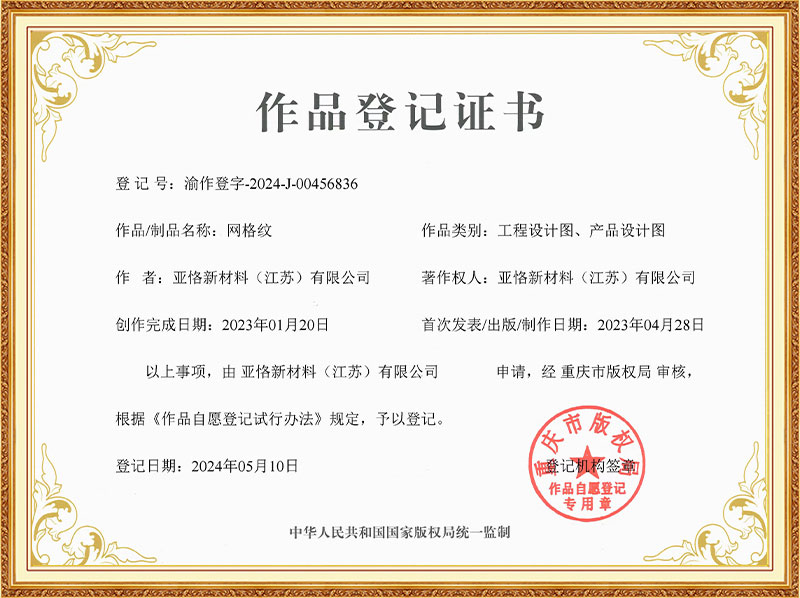

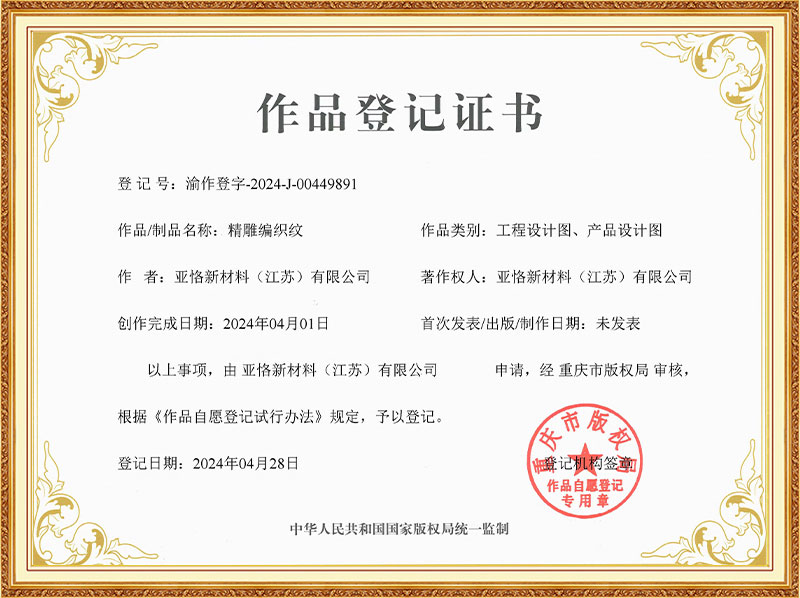

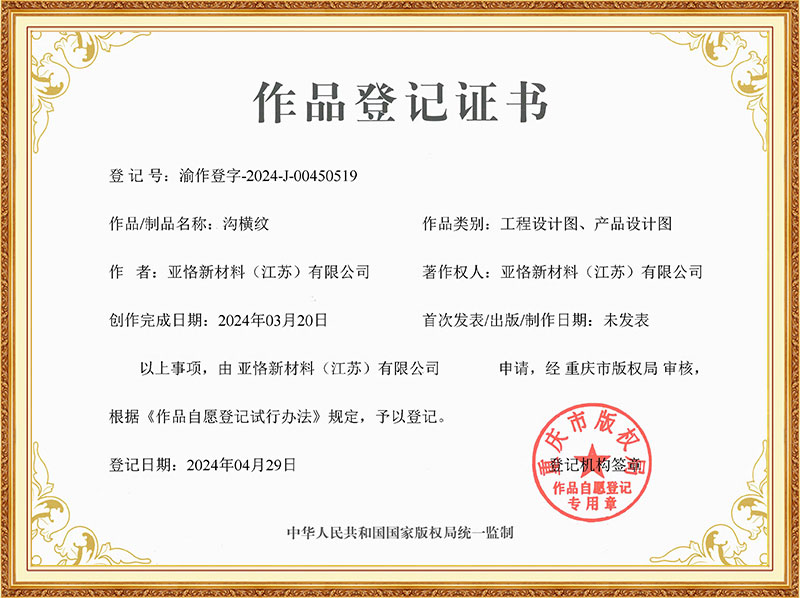

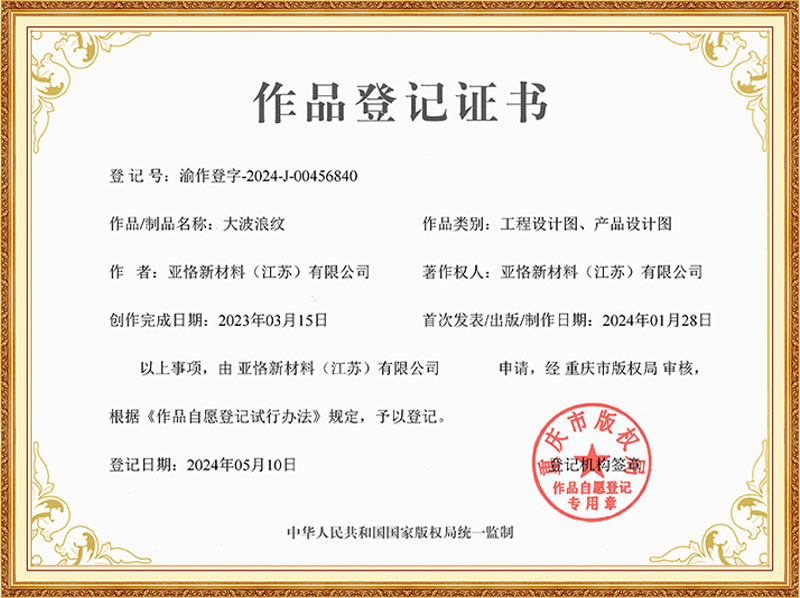

——YAKCO's 3D deep pressure subverts the quality of the decorative panels, formulates new 3D texture standards, and three-dimensional presentation effects, becoming the pioneer of 3D decorative panel technology innovation, breaking the situation that imported triamine finishes monopolize the domestic high-end market, and constantly innovating to strengthen our own high-end triamine decorative panel brand in China.

——YAKCO adopts six core production processes, which distinguish it from traditional plain board production. SOSB products are more stable, easy to cut, and less prone to deformation.

——YAKCO uses MDI medical adhesive bonding to meet the international formaldehyde content standard ENF level for boards, making it a truly healthy and environmentally friendly substrate. It is more suitable for customizing indoor home products and can bring consumers a healthier and more environmentally friendly home environment.

In the evolving world of surface materials, the Leather Design Melamine Board stands out as a sophisticated fusion of material science and aesthetic artistry. This specialized board is engineered to bridge the gap between the opulent sensor...

View MoreIn the evolving landscape of interior materials, the Fabric Design Melamine Board has emerged as a revolutionary solution for those seeking the tactile warmth of textiles combined with the structural integrity of engineered wood. Specifical...

View MoreIn the sophisticated world of high-end interior design and cabinetry, the quest for the perfect balance between the organic beauty of nature and industrial-grade durability is unending. While solid wood has long been the traditional choice,...

View More1. Definition and Application of Frosted 3D Wall Panels

Frosted 3D wall panels are a kind of wall decoration material that is both artistic and functional. It gives the wall a rich sense of layering and touch through a unique three-dimensional effect and frosted treatment. This material is usually made of environmentally friendly materials such as PVC, gypsum, wood, composite resin, etc., which can meet the dual needs of modern interior design for aesthetics and practicality. As a leading manufacturer in the industry, YAKCO New Materials (Jiangsu) Co., Ltd. provides a variety of innovatively designed frosted 3D wall panels, aiming to meet different market needs through excellent product quality and unique design.

These wall panels are not just decorative elements of the wall, they also have advantages such as acoustic effects, sound insulation and durability. The frosted surface can effectively reduce the light reflected from the wall through meticulous craftsmanship, creating a softer visual experience. The 3D effect can effectively enhance the sense of layering of the space, making the entire space more modern and artistic. Whether it is a modern family home, commercial office, hotel lobby, or high-end exhibition space, frosted 3D wall panels can bring personalized charm to each space.

For users who like modern minimalist style, the 3D wall panels provided by YAKCO New Materials (Jiangsu) Co., Ltd. are mainly designed with simple and smooth lines, which can be perfectly integrated with other furniture and decorative elements. For the design style that pursues a natural and warm atmosphere, the 3D panels that imitate wood grain or stone grain can bring a comfortable and harmonious effect.

2. The production process of frosted 3D wall panels

The production process of frosted 3D wall panels is quite complicated, and a series of precise steps are required to ensure the quality and effect of the final product. As a leader in the industry, YAKCO New Materials (Jiangsu) Co., Ltd. always adheres to innovation and refined management, and continuously optimizes the production process to ensure that each wall panel meets high standards of quality requirements.

a. Mold design

The production of frosted 3D wall panels starts with fine mold design. The quality of the mold directly affects the final effect of the panel, especially the 3D effect and the treatment of the frosted surface. The YAKCO team uses the most advanced 3D modeling technology for design and precision molds through CNC machine tools and laser engraving technology. The meticulous mold design not only perfectly presents the complex three-dimensional effect, but also ensures that the size and shape of each panel are consistent.

b. Material selection

YAKCO New Materials (Jiangsu) Co., Ltd. pays great attention to environmental protection and durability in material selection. Commonly used materials include PVC, composite resin, gypsum, etc. Each material has its own unique advantages. For example, PVC is light and easy to install, suitable for a wide range of applications; composite resin is widely used in commercial spaces for its strength and durability; gypsum is favored in high-end places for its fireproof performance. The company ensures that all materials meet international environmental standards, and the products are not only beautiful but also have excellent environmental performance.

c. Surface treatment

The frosted effect is usually achieved through precise sandblasting, polishing and other processes. In order to enhance the visual effect and feel, YAKCO has invested a lot of research and development in surface treatment, striving to achieve the best touch and visual layering. Through reasonable surface treatment, frosted 3D wall panels can effectively avoid reflecting light, making the wall softer and creating a comfortable space atmosphere. The frosted surface also has good stain resistance and is easy to clean and maintain.

d. Molding and assembly

Once the mold, materials, and surface treatment are completed, the next step is to integrate these elements together for molding. YAKCO injects high-quality materials into the mold through injection molding or compression molding, and then molds them after heating or cooling. This process requires a high degree of technical guarantee to ensure the accuracy and stability of the product. The panel will be polished and trimmed to ensure that every detail is perfectly presented to meet customer needs.

3. Market prospects and challenges

As modern people's requirements for home aesthetics and comfort increase, the market demand for frosted 3D wall panels continues to grow. As a leading manufacturer of wall decoration materials, YAKCO New Materials (Jiangsu) Co., Ltd. is committed to promoting the development of the industry and creating more innovative 3D wall decoration materials. Although the market prospects are broad, there are also many challenges. Understanding market trends, mastering innovative designs and improving production efficiency are the keys to continued competition.

Market demand

As young consumers' demand for personalization and customization increases, frosted 3D wall panels have gradually become the first choice for many home and commercial space decoration. Modern people's aesthetic requirements for space are constantly improving, and they are no longer satisfied with a single wall decoration. They are more inclined to pursue wall materials that can bring visual impact and space changes. YAKCO has successfully occupied this market segment with its unique design style and high-quality products. Especially in modern minimalist and natural style designs, YAKCO's 3D wall panels are very popular.

Continuous innovation

In a highly competitive market environment, continuous innovation is the key to maintaining a leading position in the market. YAKCO not only innovates in product design, but also continuously explores new environmentally friendly materials and process technologies to improve the performance and aesthetics of products. The company has launched a variety of series of frosted 3D wall panels, including a modern style series with simple and smooth lines, and a series that simulates natural textures, which successfully meet the needs of different customers for decorative effects.

Challenges faced

Despite the promising market prospects, the frosted 3D wall panel industry still faces multiple challenges. The cost fluctuation of raw materials is an issue that manufacturers must deal with. Technological updates in the production process also require manufacturers to continue to invest in research and development to improve production efficiency and reduce costs. The increasingly fierce market competition, especially the impact of low-priced products, requires brand companies to not only provide high-quality products, but also pay attention to customer service and marketing strategies to maintain brand competitiveness.